The ideal situation as far as I am concerned is to have a clutch in the electric motor output to take up any lumps and bumps in the start up sequence of the controller and also reduce the transmission load if you have a multi blade head with big heavy blades.. I favor the Robbe clutches because a) I have a lot of them and b) I can change them easily to give me many variations on gear ratios.

This time I started with an Actro motor as I had one to hand but I have also done this with the big Plettenberg 370 motor. I start by drilling a 4.5 mm diameter hole down the center of the output shaft. The Actro already has a small hole in the center so that makes it easy and the easy way to do the Pletteneberg or any other inrunner is to have the motor running while you do it. That will automatically center the drill.

Tap the hole out to 5mm. Now you need the stock Robbe clutch assembly. I have cut some of mine down in the lathe to lower the height but leaving it stock will work just fine.

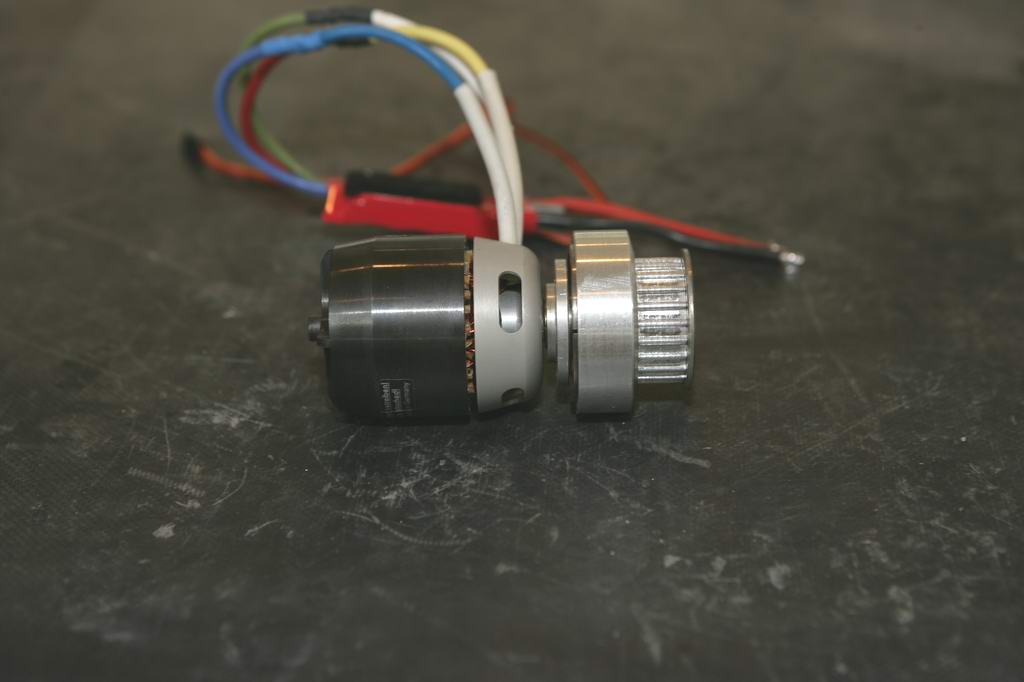

This is the sequence of assembly of the parts.

Partly assembled with the clutch key in place

And all pushed together and tightened up with the 5mm bolt. The grip on the shaft is by the tapered brass collet and because the power output is a smooth series of pulses rather than one bang per revolution as with a glow motor, the 5mm screw will easily provide enough locking force to stop anything slipping.